Project Description

Custom Lens and Illumination System

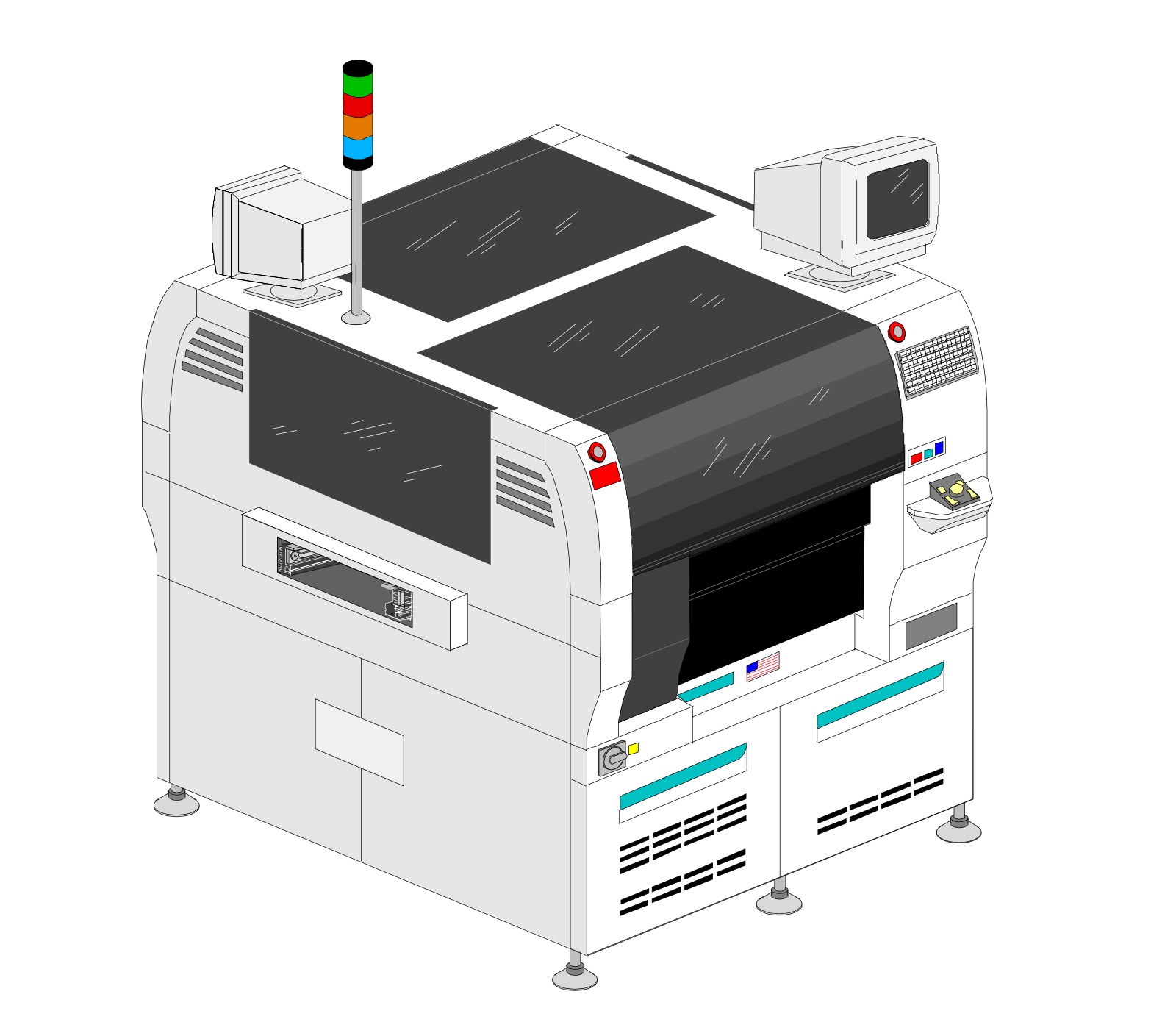

When a manufacturer needed an upgrade to increase the production rate of their high speed pick and place machine, INOV was able to design a custom lens and illumination system that surpassed their specifications.

The customer’s goal was to replace the machine’s 3-headed camera with a 7-headed one. They also needed new lens designs for the cameras and a challenging custom illumination system – used to light a wide variety of irregularly shaped components. Their hope was to double the production rate at which the automated machine could place surface mount components onto circuit boards.

INOV created products that met the customer’s requirements and more than doubled the machine’s efficiency, raising the machine’s output from 14,000 surface mount components per hour to 30,000 per hour.